Back to top

We are globally famous for Digital Production Display, Token Counter Display, Digital LED Clock Display, Street Light Timer Switch Display, Power Control Panel, and more.

Kul Systems is a reliable manufacturer and supplier of Digital Production Display, Token Counter Display, Digital LED Clock Display, Street Light Timer Switch Display, Power Control Panel, and more. We are also a leading service provider offering Plastic Injection Moulding Service, etc. Our services adhere to international standards. Our offerings are highly regarded by clients worldwide. Our products are characterized by their reliability, flexibility, robust design, and meticulous programming.

We are supported by a team of experts and highly trained professionals who assist us in meeting the varied needs of our clients. Our quality control team meticulously inspects each product for defects and faults. Only after passing rigorous quality checks do we approve products for final dispatch. We are equipped to meet all client requirements efficiently, ensuring timely delivery of our next batch of offerings. To facilitate this process, we maintain a spacious warehouse for the storage of our extensive inventory. Furthermore, we provide superior transportation services within specified timeframes.

Infrastructure

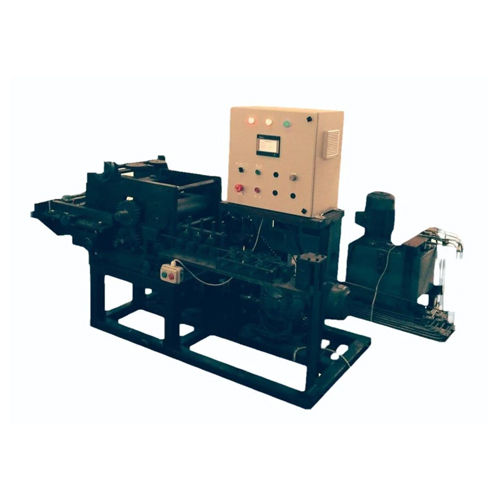

In order to adapt to the diverse and evolving technological advancements within the industry, we have established a robust infrastructure for our company. Our efficiently managed infrastructure enables us to enhance our operational effectiveness and optimize time utilization. Furthermore, we employ cutting-edge techniques that facilitate the production of high-quality products in substantial quantities, ensuring minimal defects. We consistently strive to create products that reflect the standards of our company, not only on a national scale but also globally.

Why Choose Us?

Listed below are a few factors that sets us apart:

Vision

Our vision is:

We are supported by a team of experts and highly trained professionals who assist us in meeting the varied needs of our clients. Our quality control team meticulously inspects each product for defects and faults. Only after passing rigorous quality checks do we approve products for final dispatch. We are equipped to meet all client requirements efficiently, ensuring timely delivery of our next batch of offerings. To facilitate this process, we maintain a spacious warehouse for the storage of our extensive inventory. Furthermore, we provide superior transportation services within specified timeframes.

Infrastructure

In order to adapt to the diverse and evolving technological advancements within the industry, we have established a robust infrastructure for our company. Our efficiently managed infrastructure enables us to enhance our operational effectiveness and optimize time utilization. Furthermore, we employ cutting-edge techniques that facilitate the production of high-quality products in substantial quantities, ensuring minimal defects. We consistently strive to create products that reflect the standards of our company, not only on a national scale but also globally.

Why Choose Us?

Listed below are a few factors that sets us apart:

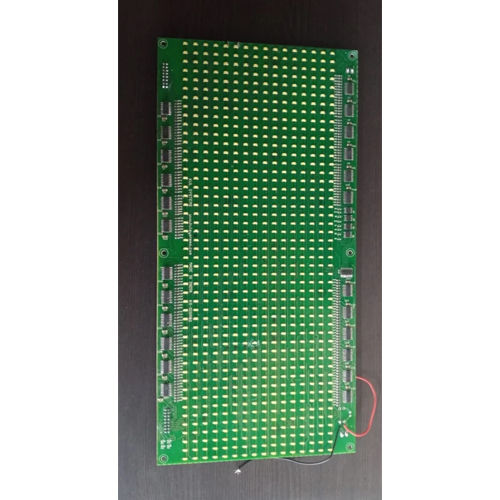

- Miniaturization- Achieving higher packing density, fine pitch component assembly, and a process-oriented approach.

- Enhanced Reliability- Through thermal aging and burn-in testing.

- Superior Performance- Conducting checks on the Bill of Materials (BOM) in accordance with Electrical Rule Check (ERC), Design Rule Check (DRC), conditional placement, signal integrity, and EMI/EMC considerations.

- Adaptability- Flexibility in implementing engineering changes due to a lean process approach and the maintenance of data and offline documentation support.

- Cost Efficiency- Reduction in costs associated with PCBs, components, assembly, and repairs.

- High Production Volumes- Leveraging automated processes, design for manufacturability, and process capability.

- Adherence to Quality Standards

Vision

Our vision is:

- To achieve recognition as the leading and most cost-effective provider of electronics manufacturing services within the organized corporate sector.

- Encourage team members to adopt a broader perspective and establish objectives with a focus on execution and outcomes.

- Foster a culture of respect, training, and empowerment among employees to enhance their confidence and decision-making skills.

- Embrace innovation, integration, and active participation, prioritizing vision over mere supervision. Create systems that prioritize customer satisfaction and continuous improvement.

Send Inquiry

Send Inquiry Call Me Free

Call Me Free